- Home

- Products

- About Us

- Application

- News

- Contact Us

Web Menu

- Home

- Products

- About Us

- Application

- News

- Contact Us

Product Search

Exit Menu

How Does a Stator for Power Tools Affect Performance and Durability?

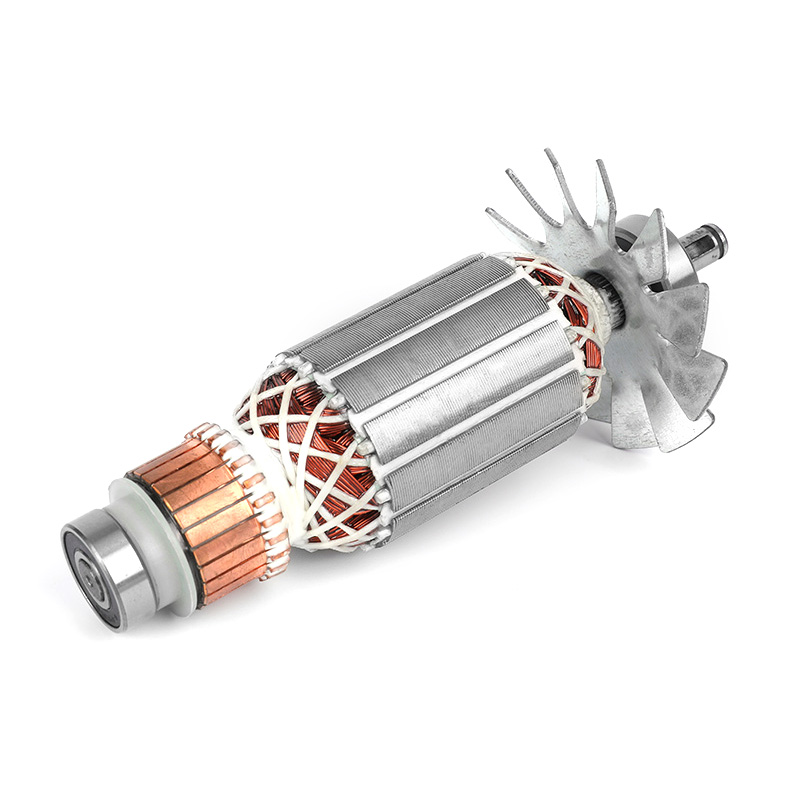

Power tools are essential for construction, woodworking, and home improvement projects. At the heart of every electric motor in these tools is a stator for power tools, a critical component that helps convert electrical energy into mechanical motion. Understanding its function, production, and quality considerations helps manufacturers and buyers ensure reliable and efficient tool performance.

What Is a Stator for Power Tools?

A stator for power tools is the stationary part of an electric motor. It typically consists of a laminated steel core wrapped with insulated copper wire windings. When electric current passes through these windings, a magnetic field is generated, which interacts with the rotor to produce rotation.

In power tools, the stator directly influences torque, speed, and efficiency. A well-designed stator allows the motor to operate smoothly under varying loads while maintaining consistent performance.

Material Selection and Manufacturing

Material choice is critical for a stator for power tools. The laminated steel core reduces energy losses due to eddy currents, while the copper windings provide efficient electrical conductivity. Insulation materials are also important to prevent short circuits and to withstand heat generated during operation.

Manufacturing a stator involves several precise steps:

- Cutting and stacking laminated steel sheets to form the core

- Winding insulated copper wire around specific poles

- Securing windings with varnish or resin for mechanical stability

- Testing electrical resistance, insulation quality, and magnetic properties

These steps ensure that each stator performs reliably and can handle the stresses of continuous or heavy-duty use.

Design Considerations for Power Tools

Designing a stator for power tools requires careful attention to size, weight, and winding configuration. The stator must fit within the compact housing of the tool while providing sufficient magnetic flux to drive the rotor efficiently.

Manufacturers consider factors such as voltage, current, and duty cycle when designing stators. Proper design helps prevent overheating, reduces energy loss, and ensures that the tool maintains consistent torque across different speeds.

Quality Control and Testing

Quality control is essential for a stator for power tools. Factories perform inspections and tests to verify:

- Winding resistance and continuity

- Insulation strength and heat resistance

- Mechanical stability of the laminated core

- Dimensional accuracy to ensure proper assembly

Testing helps identify defects early, preventing premature motor failure and ensuring that the finished power tools perform reliably in various applications.

Customization and Application

Different power tools require different stator designs. A stator for a handheld drill may prioritize compact size and light weight, while a stator for a bench grinder may focus on torque and heat dissipation. Manufacturers often provide customized windings, laminations, or insulation options to meet these requirements.

Custom stators allow tool makers to produce machines that balance performance, durability, and user convenience. They are crucial for both industrial-grade tools and consumer-grade equipment.

Value for Buyers and Manufacturers

For buyers and manufacturers, working with a reliable stator supplier ensures consistent quality, technical support, and timely delivery. Understanding how stators are produced and tested allows buyers to select components that match the electrical and mechanical specifications of their tools, reducing maintenance needs and improving overall tool lifespan.

A stator for power tools is a fundamental component that directly affects the performance, durability, and efficiency of electric tools. From material selection and precision winding to testing and customization, every step in its production contributes to reliable motor operation. Awareness of these factors helps manufacturers and buyers choose stators that meet operational needs while supporting long-term tool performance.

-

Add: 1st Floor, No. 2, Huanan Road, Zhengcun, Economic Development Zone, Yongkang City, Zhejiang Province, China

-

Tel: +86-0579-87133113

-

E-mail: [email protected]

English

English русский

русский Español

Español