- Home

- Products

- About Us

- Application

- News

- Contact Us

Web Menu

- Home

- Products

- About Us

- Application

- News

- Contact Us

Product Search

Exit Menu

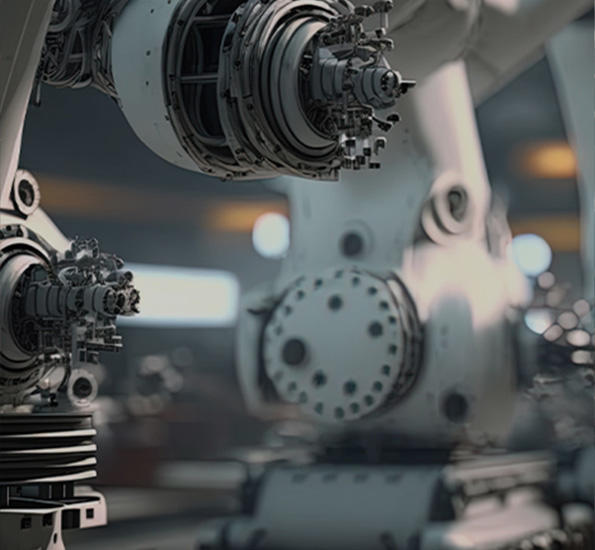

The Importance of Stator Maintenance for Smooth Electric Tool Operation

China Wholesale Stator For Power Tools Manufacturer Factory

In the realm of power tools, the stator is an often underestimated yet crucial element that guarantees the smooth operation of these indispensable machines. As a manufacturer, CREATOR is keenly aware of the importance of maintaining the stator to ensure that your power tools perform at their optimal level without fail.

The stator, a key component within the electric motor of power tools, is responsible for creating the magnetic field necessary for the tool's operation. It is composed of multiple windings that, when energized, interact with the rotor to produce torque. However, over time, the stator can be subject to wear and tear, which can lead to a decrease in performance or even tool failure. That's why, as a manufacturer, we emphasize the importance of regular stator maintenance for power tools.

To begin with, understanding the signs of a failing stator is essential. If your power tool is experiencing issues such as reduced power, excessive heat, or unusual noises, these could be indicative of a problem with the stator. Early detection can prevent more severe damage and costly repairs.

Maintenance of the stator for power tools involves several steps. First and foremost, regular cleaning is essential to remove dust and debris that can accumulate over time and affect the stator's performance. Using a soft brush or compressed air, gently remove any particles that could interfere with the stator's operation. Next, inspect the stator for any signs of damage, such as cracks or corrosion, which could compromise the integrity of the windings. If you notice any such issues, it's crucial to replace the stator promptly to prevent further damage to the motor.

Another aspect of stator maintenance for power tools is ensuring that the connections to the stator are secure and free from corrosion. Loose or corroded connections can lead to intermittent operation or complete failure of the tool. Regularly check the wiring and terminals, tightening any loose connections and cleaning off any corrosion to maintain a strong electrical connection.

Beyond routine maintenance, it's also important to use the power tools as intended. Overloading the motor or using the tool in environments that are too dusty or wet can lead to premature stator failure. Following the manufacturer's guidelines for use and care is a simple yet effective way to extend the life of the stator and the tool as a whole.

As a manufacturer, we understand that downtime can be costly, which is why we prioritize the design and construction of durable stators that can withstand the rigors of daily use. However, even the most robust components require care and attention to maintain their performance over time. By investing in the proper maintenance of the stator for power tools, industry users can experience fewer breakdowns, reduced repair costs, and increased productivity.

In conclusion, the stator for power tools is a component that, while not always in the spotlight, plays a pivotal role in the tool's performance and longevity. By adhering to a regular maintenance schedule and being vigilant for signs of wear or damage, industry users can ensure that their power tools continue to operate smoothly and efficiently. CREATOR is committed to providing not only high-quality power tools but also the knowledge and support needed to keep these tools running.

-

Add: 1st Floor, No. 2, Huanan Road, Zhengcun, Economic Development Zone, Yongkang City, Zhejiang Province, China

-

Tel: +86-0579-87133113

-

E-mail: [email protected]

English

English русский

русский Español

Español