- Home

- Products

- About Us

- Application

- News

- Contact Us

Web Menu

- Home

- Products

- About Us

- Application

- News

- Contact Us

Product Search

Exit Menu

What Types of Carbon Brush Holders Are Used in Different Power Tools?

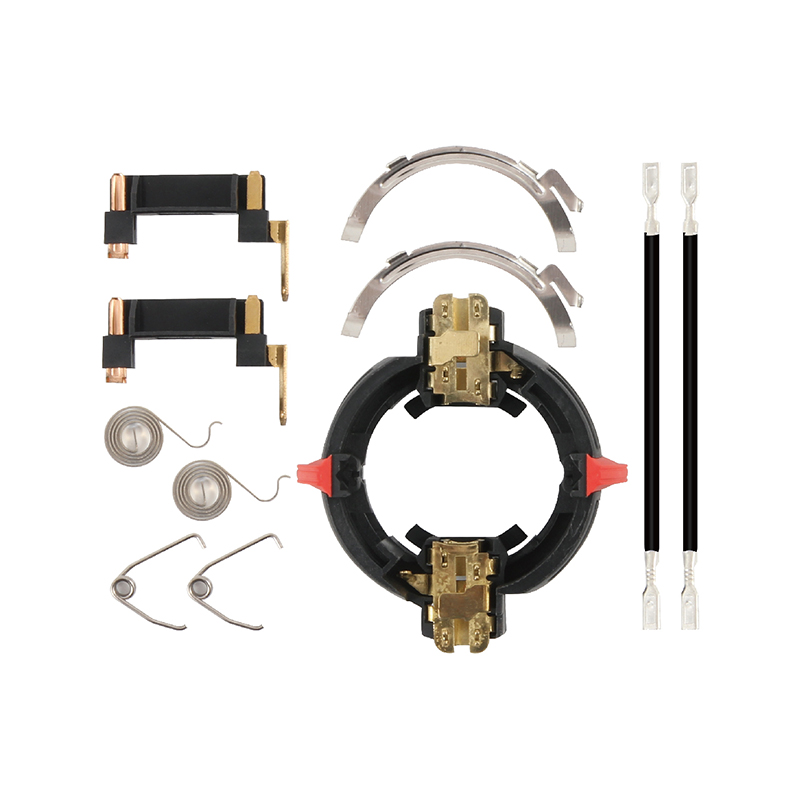

A Carbon Brush Holder For Power Tools plays a crucial role in ensuring the efficient operation of electric motors within various power tools. Carbon brushes conduct electrical current between stationary wires and the rotating parts of a motor. The holder secures these brushes in place, allowing for consistent contact with the commutator. Different types of Carbon Brush Holders For Power Tools are designed to suit the unique needs of various tools, depending on their size, power requirements, and operational conditions.

One common type of Carbon Brush Holder For Power Tools is the spring-loaded holder. This design uses a spring mechanism to maintain consistent pressure on the carbon brush, ensuring steady contact with the motor's commutator as the brush wears down. Spring-loaded holders are widely used in handheld power tools like drills, grinders, and saws. Their ability to adjust automatically to brush wear makes them practical for tools that require frequent and consistent performance.

Another type is the fixed carbon brush holder. Unlike spring-loaded versions, fixed holders secure the carbon brush in a set position without adjustable pressure. This type is often found in power tools with motors that operate under more controlled conditions, where brush wear is predictable or minimal. Fixed holders provide simplicity and durability, making them suitable for certain industrial power tools.

Some Carbon Brush Holders For Power Tools incorporate a removable or replaceable design, allowing easy replacement of brushes without dismantling the entire motor assembly. This feature is especially useful in tools that experience heavy use, where brushes may need frequent replacement. By simplifying maintenance, these holders reduce downtime and extend the working life of the tool.

In larger power tools, such as stationary saws or heavy-duty grinders, more robust carbon brush holders are used. These holders may include additional insulation or heat-resistant materials to cope with higher currents and prolonged operation. The design of the holder in these tools must consider not only mechanical stability but also thermal management, as overheating can degrade both the brushes and motor.

The materials used in Carbon Brush Holders For Power Tools also vary. Commonly, holders are made from durable plastics or composites that provide electrical insulation while resisting wear and impact. Some holders feature metal components or contacts to ensure a reliable electrical path between the carbon brush and the power tool’s circuitry.

Different power tools may also have varying requirements for brush size and shape, which influences the design of the brush holder. For example, compact cordless tools may use smaller, more compact holders to fit within limited space. On the other hand, larger tools with higher power demands often use larger brushes and holders designed to handle increased electrical load and mechanical stress.

Safety is another consideration in the design of Carbon Brush Holders for Power Tools. Proper insulation and secure mounting prevent accidental contact with electrical parts and reduce the risk of sparks or short circuits during operation. Some holders also include features to reduce vibration and noise generated by the brushes, contributing to a smoother-running tool.

The types of Carbon Brush Holders For Power Tools vary depending on the tool’s size, power, and application. Spring-loaded holders are common for handheld tools requiring adaptable brush contact, while fixed and removable holders serve specific operational and maintenance needs. Material choice and design considerations ensure that these holders provide a reliable electrical connection and mechanical support under different working conditions.

Understanding these differences helps manufacturers and users select or replace carbon brush holders that fit the particular requirements of their power tools, contributing to sustained tool performance and longevity.

-

Add: 1st Floor, No. 2, Huanan Road, Zhengcun, Economic Development Zone, Yongkang City, Zhejiang Province, China

-

Tel: +86-0579-87133113

-

E-mail: [email protected]

English

English русский

русский Español

Español