Power Tools Spare Parts

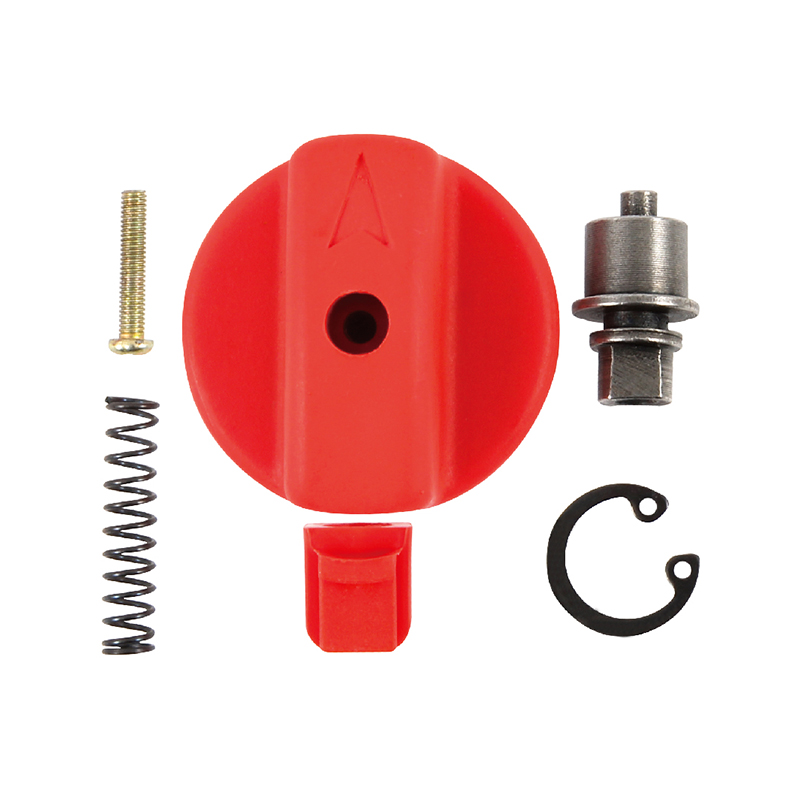

LM08-09 Power Tool Accessories

| Packing Quantity: | 500 |

| Measurement: | 22.3*36*40 |

| Weight: | 16 |

| Applicable to: | |

+86-0579-87133113

1st Floor, No. 2, Huanan Road, Zhengcun, Economic Development Zone, Yongkang City, Zhejiang Province, China

Power Tools Spare Parts

Power Tools Spare Parts

Power Tools Spare Parts

Power Tools Spare Parts

Welding Machine Spare Parts

Power Tool Switches

Suction cup

Suction cup

Suction cup

Suction cup

Suction cup

Suction cup

A crucial component in many of these tools is the piston, which plays a vital role in generating the force needed for the tool to operate efficiently. The material used for pistons in power tools must be carefully selected to balance performance, durability, and cost.

Typically, pistons for power tools are made from metals such as aluminum alloys, steel, or a combination of materials designed to resist wear and maintain structural integrity under high stress. Aluminum alloys are commonly used due to their lightweight nature, which helps reduce the overall weight of the power tool, making it easier to handle. Aluminum pistons also offer good resistance to corrosion, making them suitable for tools used in various environments.

Steel, on the other hand, is often preferred for applications requiring higher strength and durability. Steel pistons can withstand higher pressures and temperatures, making them ideal for heavy-duty tools. Additionally, steel is less likely to deform under the stress of repeated use, which increases the lifespan of the power tool. Some power tool pistons are also coated with special layers such as chrome or nickel, which improve their wear resistance and reduce friction, further enhancing their performance.

The material selection for pistons in power tools is crucial for ensuring the longevity and functionality of the tool. Whether made of aluminum, steel, or a combination, these materials must be carefully chosen to meet the specific requirements of the power tool's design.

Lithium batteries have become the standard power source for modern cordless power tools, offering several advantages over older battery technologies. One of the key characteristics of lithium batteries is their high energy density, meaning they can store more energy in a smaller, lighter package. This makes lithium-powered tools more portable and easier to handle, reducing user fatigue during extended use. Additionally, lithium batteries have a longer lifespan compared to traditional batteries, as they can withstand more charge and discharge cycles without significant degradation.

Another important feature of lithium batteries is their fast charging capability. Unlike older nickel-cadmium (NiCd) batteries, which could take several hours to recharge, lithium batteries can often be recharged in a fraction of the time. This allows for minimal downtime between tasks, enhancing productivity for professionals and DIY enthusiasts alike.

Lithium batteries also tend to perform better under a wider range of temperatures, making them suitable for use in various environmental conditions. Whether working in hot or cold conditions, lithium batteries can maintain their performance and efficiency without a significant loss of power.

Gears are integral components in many power tools, as they help transmit power from the motor to the tool's working part. The advantages of gears in power tools are numerous, contributing to the efficiency, performance, and versatility of the tools.

One of the primary advantages of gears in power tools is their ability to control the speed and torque of the tool. By adjusting the gear ratio, manufacturers can design power tools that provide power for specific tasks. For instance, a low gear ratio offers higher torque for tasks that require more force, such as drilling through concrete, while a high gear ratio allows for faster speeds, making it ideal for tasks like sanding or polishing.

Gears also help to improve the overall efficiency of power tools. By converting rotational power from the motor into the necessary motion for the tool's operation, gears ensure that more of the motor's power is effectively utilized, reducing energy waste. This not only enhances the tool's performance but also helps to extend its battery life, especially in cordless power tools that rely on batteries for power.

In addition to performance, gears contribute to the durability and longevity of power tools. High-quality gears, typically made from steel or other durable materials, can withstand the wear and tear of frequent use, ensuring the tool remains reliable over time. The precise design and material choice of gears also help reduce friction, which lowers the risk of overheating and damage.

| Packing Quantity: | 500 |

| Measurement: | 22.3*36*40 |

| Weight: | 16 |

| Applicable to: | |

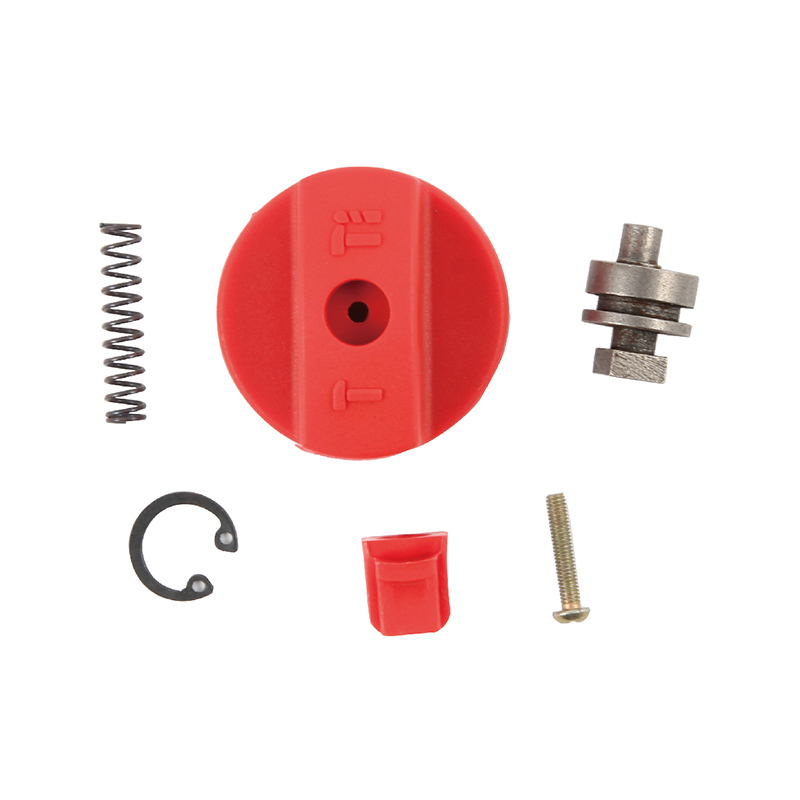

| Packing Quantity: | 500 |

| Measurement: | 22.3*36*40 |

| Weight: | 16 |

| Applicable to: | |

| Packing Quantity: | 500 |

| Measurement: | 22.3*36*40 |

| Weight: | 16 |

| Applicable to: | |

| Packing Quantity: | 500 |

| Measurement: | 22.3*36*40 |

| Weight: | 16 |

| Applicable to: | |

| Voltage: | 110V-250V |

| Current: | 4-12A |

| Working life: | 5E4 |

| Packing Quantity: | 500 |

| Measurement: | 22.3*36*40 |

| Weight: | 16 |

| Applicable to: | |

In the world of electric tools, the switch plays a crucial role in safety and functionality. It controls the flow of current and often includes features like speed control, lock-on functions, or safety cutoffs. For a switch for power tools manufacturer, ensuring that switches work seamlessly with a variety of tool types is both a technical and design challenge.

A switch in any power tool is responsible for starting and stopping the motor. In more advanced tools, it may also regulate speed, torque, or timing. When a switch for power tools manufacturer designs a switch, it must align with the specifications of the tool’s motor, voltage rating, housing structure, and intended usage. Poor compatibility can result in overheating, reduced lifespan, or even safety hazards.

One of the primary responsibilities of a switch for power tools manufacturer is to ensure that the switch can handle the electrical load of the tool. This involves matching the current and voltage requirements of the tool’s motor. For instance, a heavy-duty grinder may require a switch rated for higher amperage compared to a cordless drill.

Manufacturers conduct detailed testing to confirm that the switch can operate reliably under full load conditions. Electrical resistance, insulation, and arc suppression are also tested to ensure long-term safety and durability.

Mechanical compatibility is another area where a switch for power tools manufacturer must focus its efforts. Power tools vary widely in size, shape, and internal design. A switch must fit precisely within the tool housing while allowing smooth operation through external triggers or buttons.

Manufacturers often work closely with tool brands or follow international design standards to create switches that can be integrated into a range of tools with minimal modification. This includes designing various actuator types, mounting options, and terminal placements to suit different layouts.

Material selection is a key concern for any switch for power tools manufacturer. The internal components must be made from materials that can withstand high temperatures, repeated mechanical pressure, and exposure to dust or moisture. Contacts are usually made from copper or silver alloys, while the housing is typically a heat-resistant plastic.

To maintain compatibility across environments, switches may also be rated for water resistance or dustproofing, especially for outdoor or industrial applications. This ensures the switch continues to perform reliably regardless of where or how the tool is used.

Many tool brands approach a switch for power tools manufacturer with specific requirements. In these cases, manufacturers may create customized switches tailored to a particular model. This includes adjusting internal components, changing the external design, or integrating advanced features like variable speed control.

This collaborative process ensures that switches are not only compatible but also enhance the user experience by improving functionality and ergonomics.

Before a switch is approved for production, a switch for power tools manufacturer conducts multiple rounds of quality checks. These include electrical testing, endurance cycling, environmental stress tests, and compatibility assessments with actual power tool units. Only after passing these evaluations are the switches distributed for assembly.

Ensuring compatibility between switches and power tools requires a detailed understanding of electrical engineering, mechanical design, and end-user needs. A switch for power tools manufacturer balances these aspects by working with tool producers, following safety standards, and designing for flexibility. Through careful testing and design, manufacturers help ensure that each switch contributes to the safe and reliable operation of power tools in various industries.

Product Parameters

Handle Material: Engineered reinforced nylon handle

Sucker Material: Nitrile rubber

Voltage:3.7V

Sucker Diameter:200mm

Bearing capacity:230KGS

Vertical tension: 230KGS(limit value) 170KGS(safe value)

Horizontal tension: 200KGS(limit value) 140KGS(safe value)

2 batteries,1battery(1500mAh/10C)

One electric one charging configuration

Packaging/Material

Carton box package: 20sets/CTN

Size:58.5*44*44cm/0.12CBM/22KGS

Blow molding box package:10sets/CTN

Size:53*24*55cm/0.07CBM/17KGS

Product Parameters

Handle Material: Engineered reinforced nylon handle

Sucker Material: Nitrile rubber

Sucker Diameter:200mm

Bearing capacity:200KGS

Vertical tension: 200KGS(limit value) 160KGS(safe value)

Horizontal tension: 170KGS(limit value) 130KGS(safe value)

Packaging/Material

Carton box package: 20sets/CTN

Size:58.5*44*44cm/0.12CBM/22KGS

Blow molding box package:10sets/CTN

Size:53*24*55cm/0.07CBM/17KGS

Product Parameters

Handle Material: Engineered reinforced nylon handle

Sucker Material: Nitrile rubber

Sucker Diameter:200mm

Bearing capacity:200KGS

Vertical tension: 200KGS(limit value) 160KGS(safe value)

Horizontal tension: 170KGS(limit value) 130KGS(safe value)

Packaging/Material

Carton box package: 20sets/CTN

Size:58.5*44*44cm/0.12CBM/22KGS

Blow molding box package:10sets/CTN

Size:53*24*55cm/0.07CBM/17KGS

Product Parameters

Handle Material: Engineered reinforced nylon handle

Sucker Material: Nitrile rubber

Sucker Diameter:200mm

Bearing capacity:210KGS

Vertical tension: 210KGS(limit value) 165KGS(safe value)

Horizontal tension: 180KGS(limit value) 135KGS(safe value)

Packaging/Material

Carton box package: 20sets/CTN

Size:58.5*44*44cm/0.12CBM/22KGS

Blow molding box package:10sets/CTN

Size:53*24*55cm/0.07CBM/17KGS

A006

Product Parameters

Handle Material: Engineered reinforced nylon handle

Sucker Material: Nitrile rubber

Sucker Diameter:200mm

Bearing capacity:220KGS

Vertical tension: 220KGS(limit value) 170KGS(safe value)

Horizontal tension: 180KGS(limit value) 140KGS(safe value)

Packaging/Material

Carton box package: 20sets/CTN

Size:58.5*44*44cm/0.12CBM/22KGS

Blow molding box package:10sets/CTN

Size:53*24*55cm/0.07CBM/17KGS

B002

Product Parameters

Handle Material: Engineered reinforced nylon handle

Sucker Material: Nitrile rubber

Sucker Diameter:200mm

Bearing capacity:200KGS

Vertical tension: 200KGS(limit value) 160KGS(safe value)

Horizontal tension: 170KGS(limit value) 130KGS(safe value)

Packaging/Material

Carton box package: 20sets/CTN

Size:58.5*44*44cm/0.12CBM/22KGS

Blow molding box package:10sets/CTN

Size:53*24*55cm/0.07CBM/17KGS

Power tools rely on precise and reliable components to function safely and efficiently. Among these, the swit...

READ MOREPower tools rely on efficient electric motors to function, and the stator for power tools plays a central rol...

READ MORESwitches are crucial components in power tools, controlling functionality, safety, and efficiency. For manufa...

READ MOREPower tools are essential for DIY enthusiasts, offering convenience and efficiency for a variety of tasks. Th...

READ MOREAdd: 1st Floor, No. 2, Huanan Road, Zhengcun, Economic Development Zone, Yongkang City, Zhejiang Province, China

Tel: +86-0579-87133113

E-mail: [email protected]