- Home

- Products

- About Us

- Application

- News

- Contact Us

Web Menu

- Home

- Products

- About Us

- Application

- News

- Contact Us

Product Search

Exit Menu

How Does Manufacturing Affect the Performance of a Stator for Power Tools?

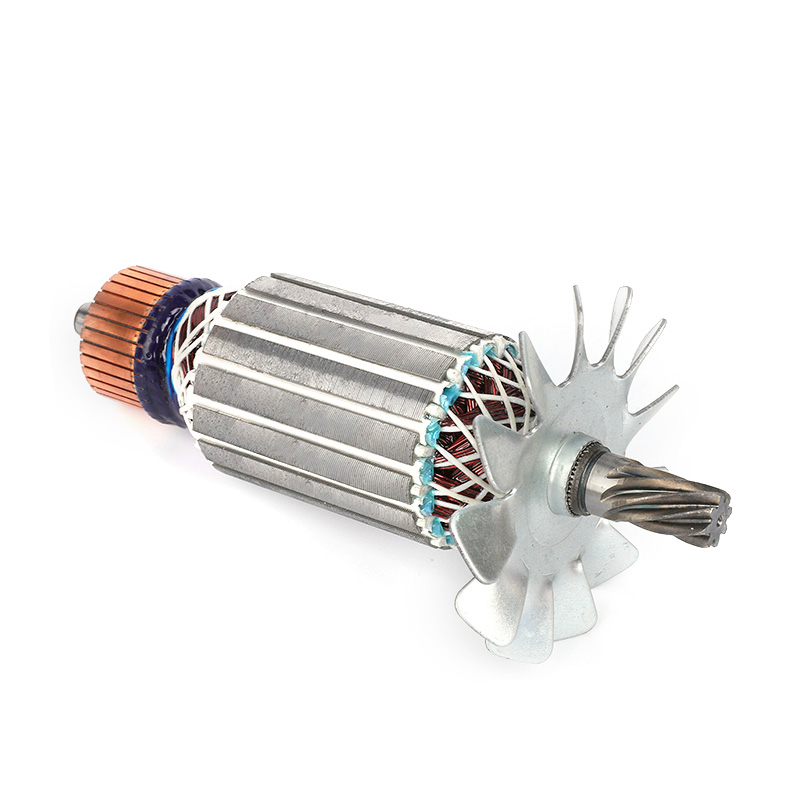

Electric motors are the backbone of power tools, and a well-constructed stator for power tools is essential to their operation. The stator generates the magnetic field that drives the rotor, directly affecting efficiency, durability, and safety. Manufacturing these components involves careful material selection, precise assembly, and thorough testing to ensure they meet performance standards.

Material Selection and Core Preparation

The step in producing a stator is selecting high-quality materials. Laminated silicon steel sheets are commonly used for the stator core due to their ability to reduce energy loss caused by eddy currents. These laminations are stacked and bonded to form the core while maintaining precise alignment.

Copper or aluminum wires are chosen for the windings, valued for their electrical conductivity and resistance to heat. Insulation materials are applied to prevent short circuits and maintain safety. Proper material choice is fundamental to achieving consistent motor performance.

Winding the Stator

The winding process is critical in a stator for power tools factory. Coils are carefully wound around the stator core using automated machines to maintain consistent tension and accurate turn counts. Even small inconsistencies can impact the strength of the magnetic field and reduce motor efficiency.

After winding, the coils are coated with insulation varnish or protective resin. This step enhances durability, protects against vibration, and provides thermal stability under continuous operation.

Assembly and Impregnation

Once the winding is complete, the stator is assembled with other components such as terminals or housings. Resin impregnation is often applied to secure the windings and improve heat dissipation. This treatment also protects the stator from dust, moisture, and mechanical stress, extending its service life in power tools that operate in demanding conditions.

Quality Control and Testing

Quality assurance is a major focus in the production of stators. Factories conduct electrical tests to measure resistance, insulation integrity, and continuity. Mechanical inspections ensure proper alignment, core assembly, and winding accuracy. Some manufacturers also perform vibration and thermal tests to simulate real operating conditions.

This rigorous testing ensures that each stator for power tools meets both safety and performance requirements, providing reliability for end users.

Customization and Adaptation

Different power tools have varying power, speed, and size requirements. A stator for power tools factory often offers customization, including variations in core size, winding type, voltage rating, or mounting design. This flexibility allows stators to fit drills, grinders, saws, or industrial tools with precision and efficiency.

Factory Practices and Workflow

Maintaining a structured production workflow is essential. Factories organize equipment, maintain machine calibration, and document processes to ensure consistency. Skilled technicians monitor winding, assembly, and testing stages, reducing the risk of defects and improving output quality.

A stator for power tools is a critical element that impacts the performance, reliability, and lifespan of electric motors. From material selection and precise winding to assembly, impregnation, and testing, manufacturing requires careful attention at every step. By understanding the processes inside a factory, it becomes clear how technical expertise and quality control come together to produce stators capable of powering tools that professionals and hobbyists depend on every day.

-

Add: 1st Floor, No. 2, Huanan Road, Zhengcun, Economic Development Zone, Yongkang City, Zhejiang Province, China

-

Tel: +86-0579-87133113

-

E-mail: [email protected]

English

English русский

русский Español

Español